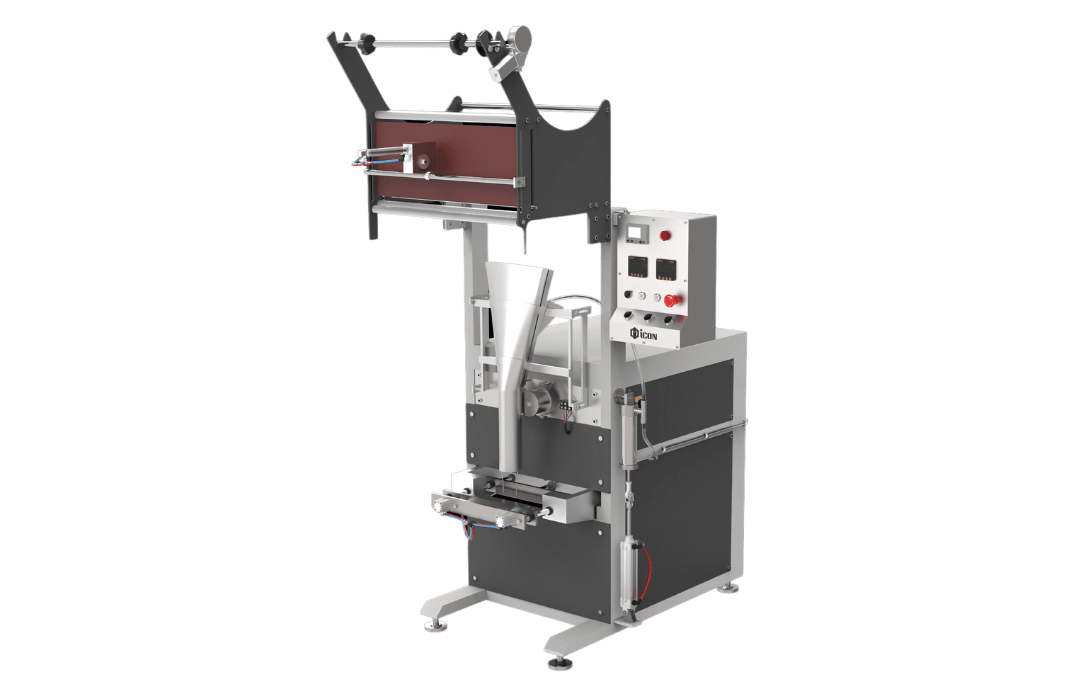

Liquid Filling VFFS Prime

Consistent Quality

International Standards

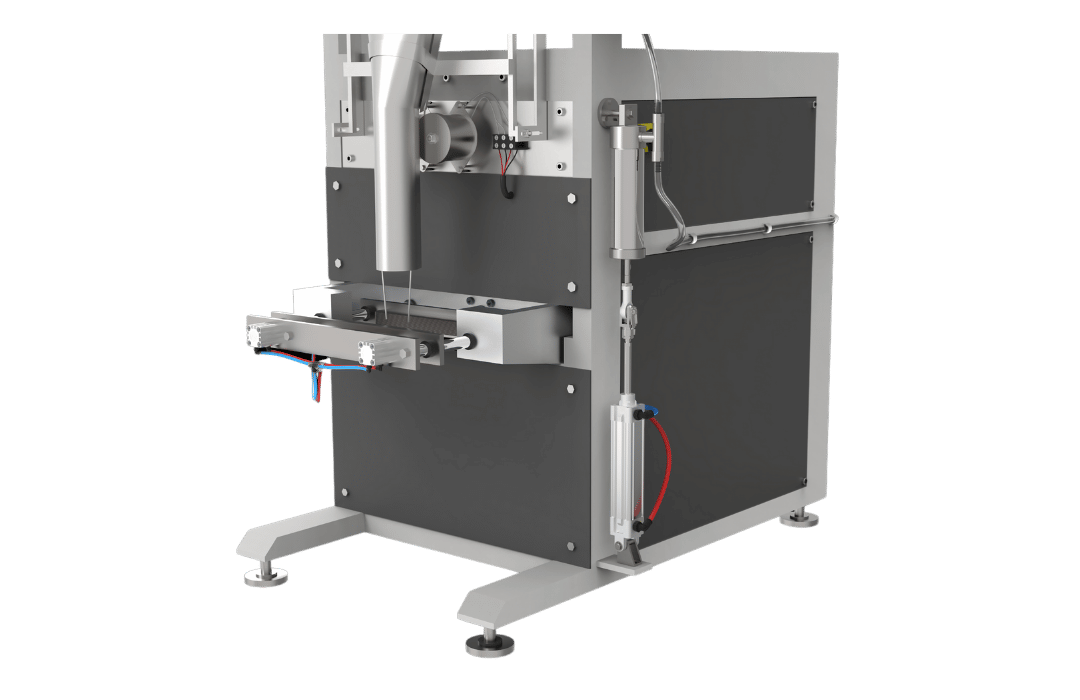

Pneumatic Operations

Secured Sealing

Safe Design

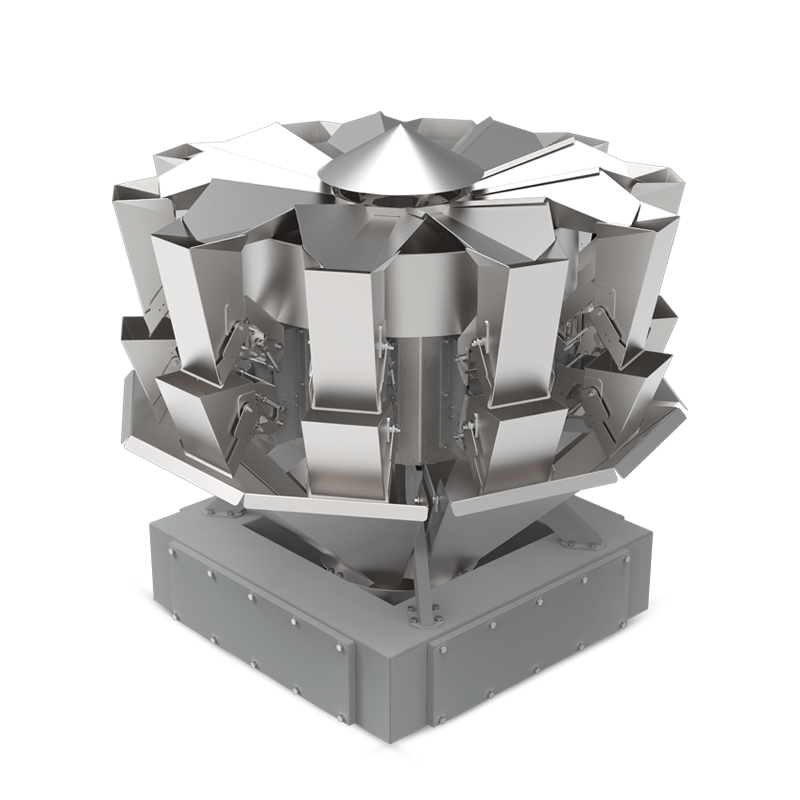

Counting Application

Types of packages

Products that can be packed

Technical Specification

Production Capacity |

||

|---|---|---|

| Cycle per Min. |

Depends on Product and Load |

|

| Pouch Volume Capacity |

10 to 500 ml (Depend on Product) |

|

| Error in Weight |

Depends on Viscosity of Product |

|

| Product Type | Food, Beverages, Pharmaceuticals, Chemicals, Oils, Detergents, Sauces, Juices, and Other Liquids | |

Machine Specification |

||

|

Hopper Capacity |

60 Ltr. (Depending on Liquid Type and Machine Configuration) |

|

|

Filling Mechanism |

Piston, Peristaltic Pump, or Volumetric Filling (Depending on Liquid Type and Application) |

|

|

Number of Pump |

1 Nos. | |

| Sealing Type |

Center Seal/Side Seal |

|

| Packing Material |

Laminated Heat Sealable Film |

|

| Automation Level | Fully Automated Filling, Sealing, and Pouch Handling | |

| Batch Coding | 35 mm x 35 mm (Printing Area) | |

Electrical Specification |

||

|

Control & Command System |

PLC & HMI 7" (Touch Screen) (Fuji) |

|

|

Power Supply |

4 KW (1-Phase) |

|

|

Heater |

Ceramic Heater (Rod Type) |

|

|

Sealing Temperature Range |

100° C to 220° C (Adjustable for Different Film Types) |

|

|

Data Logging |

Production Monitoring, Error Tracking, and Pouch Count Logging |

|

| Sensor | Photoelectric Sensors For Pouch Detection, Filling Level Control, and Sealing | |

Pneumatic Specification |

||

|

Air Pressure |

6 to 7 Bar |

|

|

Pneumatic Cylinder |

SMC |

|

|

Batch Coding |

Pneumatic |

|

Machine Structure |

||

|

Machine Construction |

M.S. Duly Powder Coated |

|

|

Contact Parts |

Food-Grade Stainless Steel for Easy Cleaning and Durability |

|

|

Machine Length |

~ 944 mm |

|

|

Machine Width |

~ 1537 mm |

|

|

Machine Hight |

~ 2034 mm |

|

|

Machine Weight |

~ 680 Kg. |

|

Optional Features |

||

| Printer | High-Quality, Durable Printing Of Variable Batch Coding And Barcodes On Flexible Packaging Printing | |

Required Accessories |

||

| Air Compressor | 3 H.P. | |

| Stabilizer | 3 KVA |

.png)

.png)

.png)

(5).png)

(6).png)

(1).png)